store and forwardmode of operation with Master and Slave SCADA Workstations

| PLC | I/O | Switch | Interface Converter | UPS | |

|---|---|---|---|---|---|

| Make | Allen Bradley | Allen Bradley | Allen Bradley | Allen Bradley | APC |

| Model | 1756-L72K | 1715-series I/O | 1783-HMS8TG4CGR (Stratix 5400) |

1766-L32BXB (MicroLogix 1400) |

SRT3000RMXLI |

| Note | Controllogix Hot Standby PLC | Hot Standby I/O | 12-port Managed Layer 3 Industrial Grade Ethernet Switch | Interfacing and signal conversion on existing PLC system at the 6 outlying stations | Smart-UPS Series |

| PLC | |

|---|---|

| Make | Allen Bradley |

| Model | 1756-L72K |

| Note | ControlLogix Hot Standby PLC |

| I/O | |

|---|---|

| Make | Allen Bradley |

| Model | 1715-series I/O |

| Note | Hot Standby I/O |

| Switch | ||

|---|---|---|

| Make | Allen Bradley | |

| Model | 1783-HMS8TG4CGR (Stratix 5400) |

1783-HMS8TG4CGR (Stratix 5400) |

| Note | 12-port Managed Layer 3 Industrial Grade Ethernet Switch |

| Interface Converter | |

|---|---|

| Make | Allen Bradley |

| Model | 1766-L32BXB (MicroLogix 1400) |

| Note | Interfacing and signal conversion on existing PLC system at the 6 outlying stations |

| UPS | |

|---|---|

| Make | APC |

| Model | SRT3000RMXLI |

| Note | Smart-UPS Series |

| HMI | Open Platform Communication (OPC) Server | Historian | |

|---|---|---|---|

| Make | Rockwell Automation | Rockwell Automation | Rockwell Automation |

| Model | FactoryTalk View Enterprise Site Edition (Network Distributed Station) |

KEPServer Enterprise | FactoryTalk Historian Site Edition |

| Note | Redundant Servers with 2 Clients for Monitoring and Control of STSTW and 6 Outlying Stations Equipment | Access Sludge Dewatering and Chemical Dosing System Monitoring | Historical Data Storage and Forwarding Operation with Master and Slave SCADA Workstations |

| HMI | |

|---|---|

| Make | Rockwell Automation |

| Model | FactoryTalk View Enterprise Site Edition (Network Distributed Station) |

| Note | Redundant Servers with 2 Clients for Monitoring and Control of STSTW and 6 Outlying Stations Equipment |

| Open Platform Communication (OPC) Server | |

|---|---|

| Make | Rockwell Automation |

| Model | KEPServer Enterprise |

| Note | Access Sludge Dewatering and Chemical Dosing System Monitoring |

| Historian | |

|---|---|

| Make | Rockwell Automation |

| Model | FactoryTalk Historian Site Edition |

| Note | Historical Data Storage and Forwarding Operation with Master and Slave SCADA Workstations |

Click photo to enlarge

Before Works

Existing PLC-5 PLC System in DSD Stanley STW Control Room

Existing PLC-5 PLC System with Part of Remote I/O Rack in DSD Stanley STW

Existing Outlying Station Communication Interface Modules in DSD Stanley STW Control Room

After Works

External View of Installed new PLC Panel at Stanley STW Switch Room (Typical)

Installed Redundant PLC Rack Power Supply and PLC Rack inside the new PLC Panel (Typical)

Close-up of Installed Redundant PLC Rack Power Supply inside the new PLC Panel (Typical)

Close-up of Installed Primary (as-is state) PLC Rack inside the new PLC Panel (Typical)

Close-up of Installed Redundant Digital Input Modules inside the new PLC Panel (Typical)

Close-up of Installed Redundant Digital Output Modules inside the new PLC Panel (Typical)

Close-up of Installed Redundant Ethernet Adapter (Pink Label) / Analogue Input (Orange Label)/ Analogue Output (Yellow Label) Modules inside the new PLC Panel (Typical)

Click photo to enlarge

After Works

External View of Installed new Server Rack at Stanley STW Control Room

Internal View of Installed new Server Rack

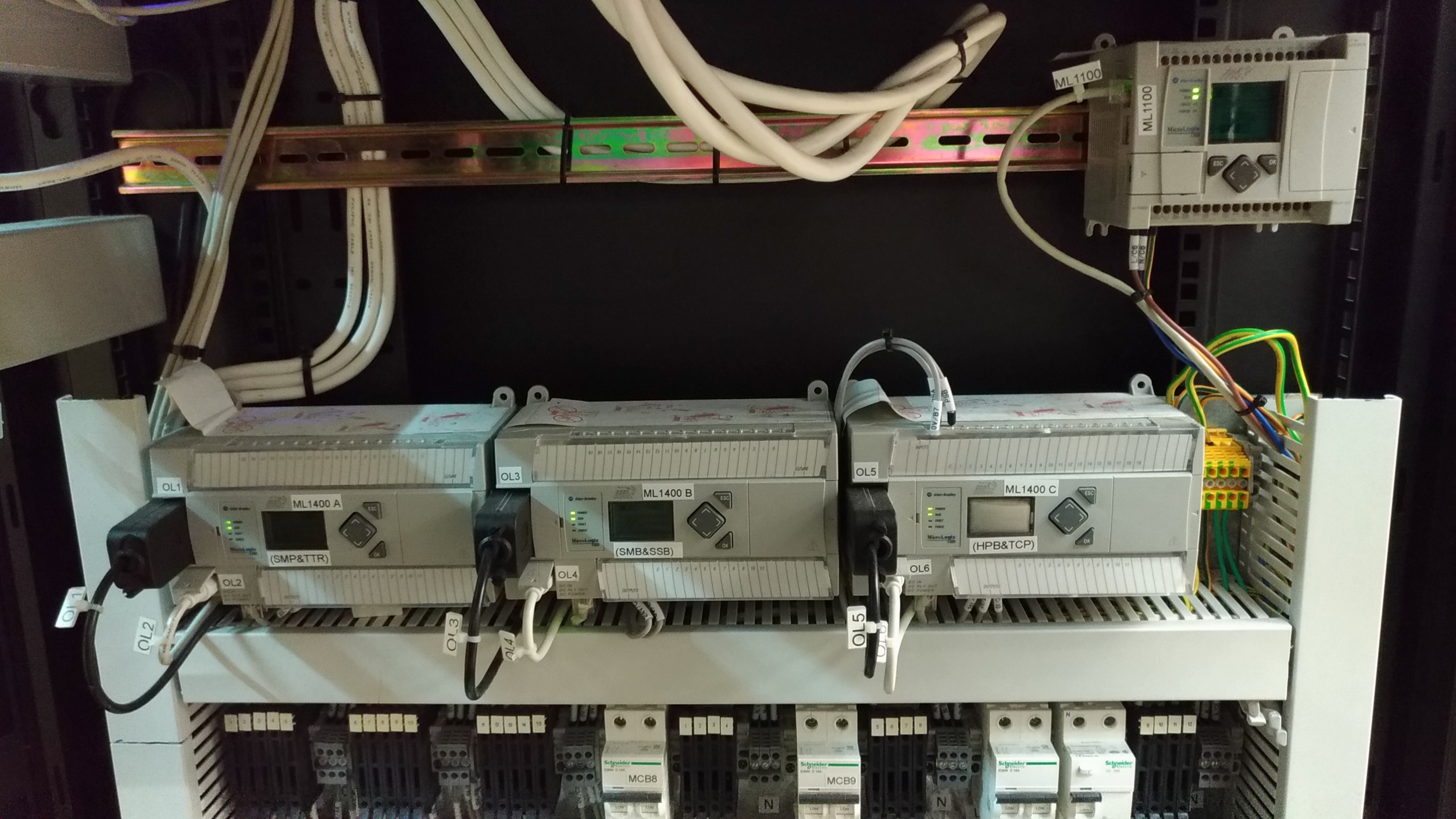

Close-up of Installed 3 Interface Converters (MicroLogix 1400) for 6 Outlying Stations inside the new Server Rack

Close-up of Installed Redundant 12-port Ethernet Switch inside the new Server Rack

Click photo to enlarge

After Works

External View of Installed new UPS Manual Bypass Panel mounted on the right side of UPS Rack at Stanley STW Switch Room

External Side View of Installed new UPS Rack

Internal View of Installed new UPS Rack

Close-up of a part of Installed UPS inside the new UPS Rack (Typical)

Close-up of Installed Redundant Isolation Transformer inside the new Server Rack

Click photo to enlarge

Before Works

Hardware to be Dismantled

Existing ControlView Workstation to be replaced by new HMI in DSD Stanley STW Control Room

Part of Existing Instrumentation Panel to be replaced by new HMI in DSD Stanley STW

Part of Existing Mosaic Type MIMIC display to be replaced by new HMI in DSD Stanley STW

Screenshots captured from ControlView

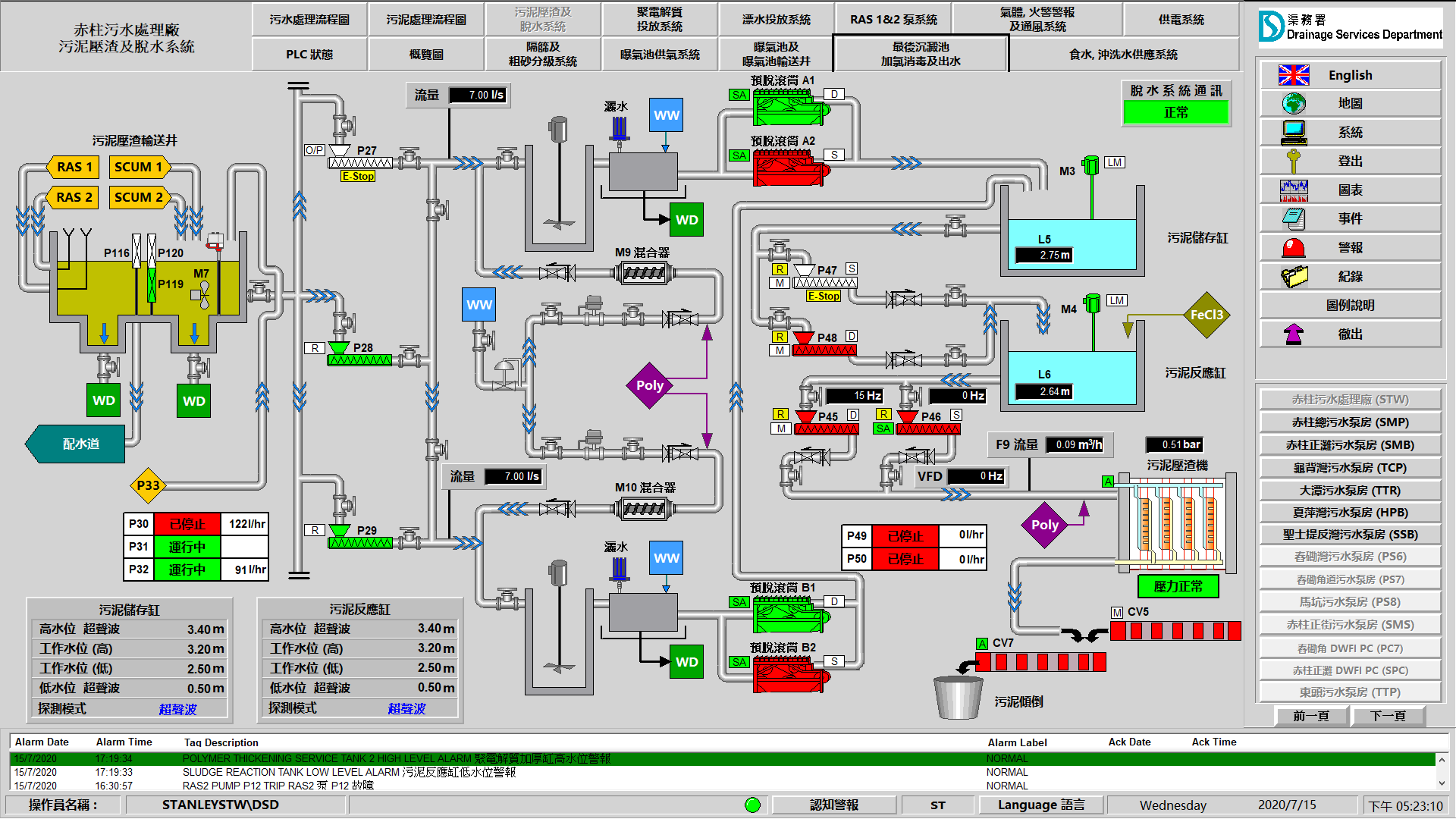

Part of Sludge Press System

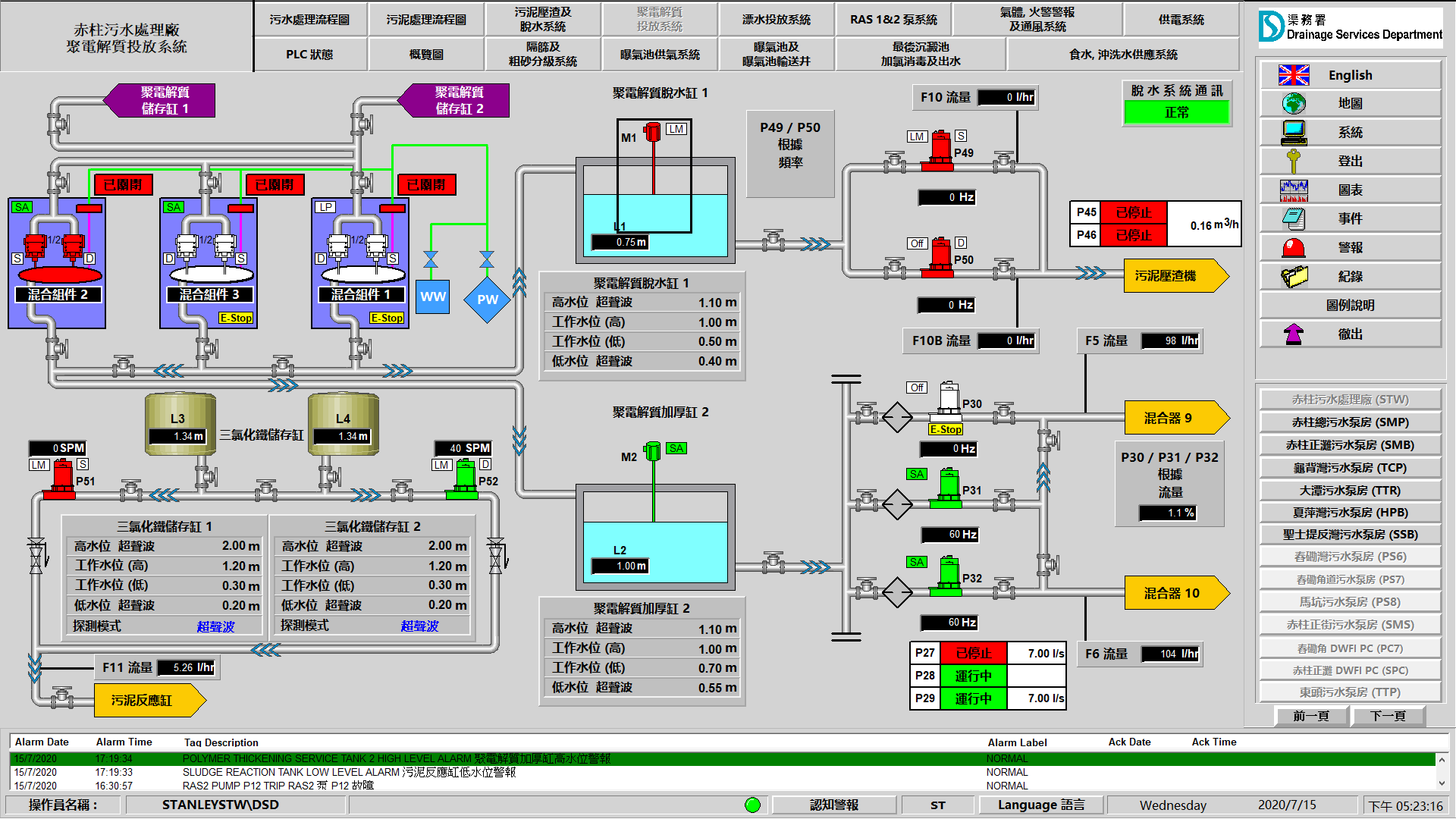

Part of Polyelectrolyte Dosing System

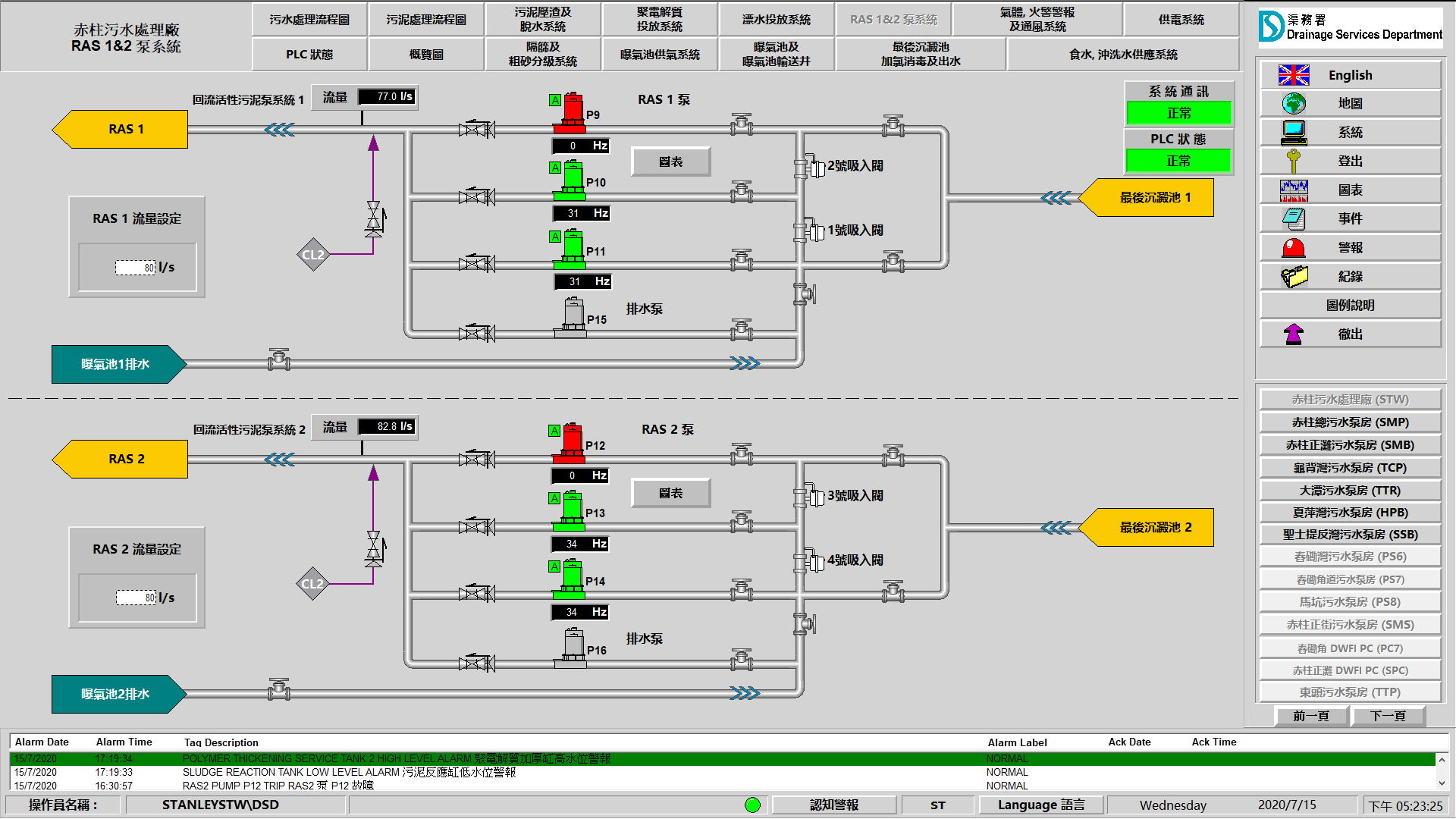

Part of RAS Pumping System (Typical)

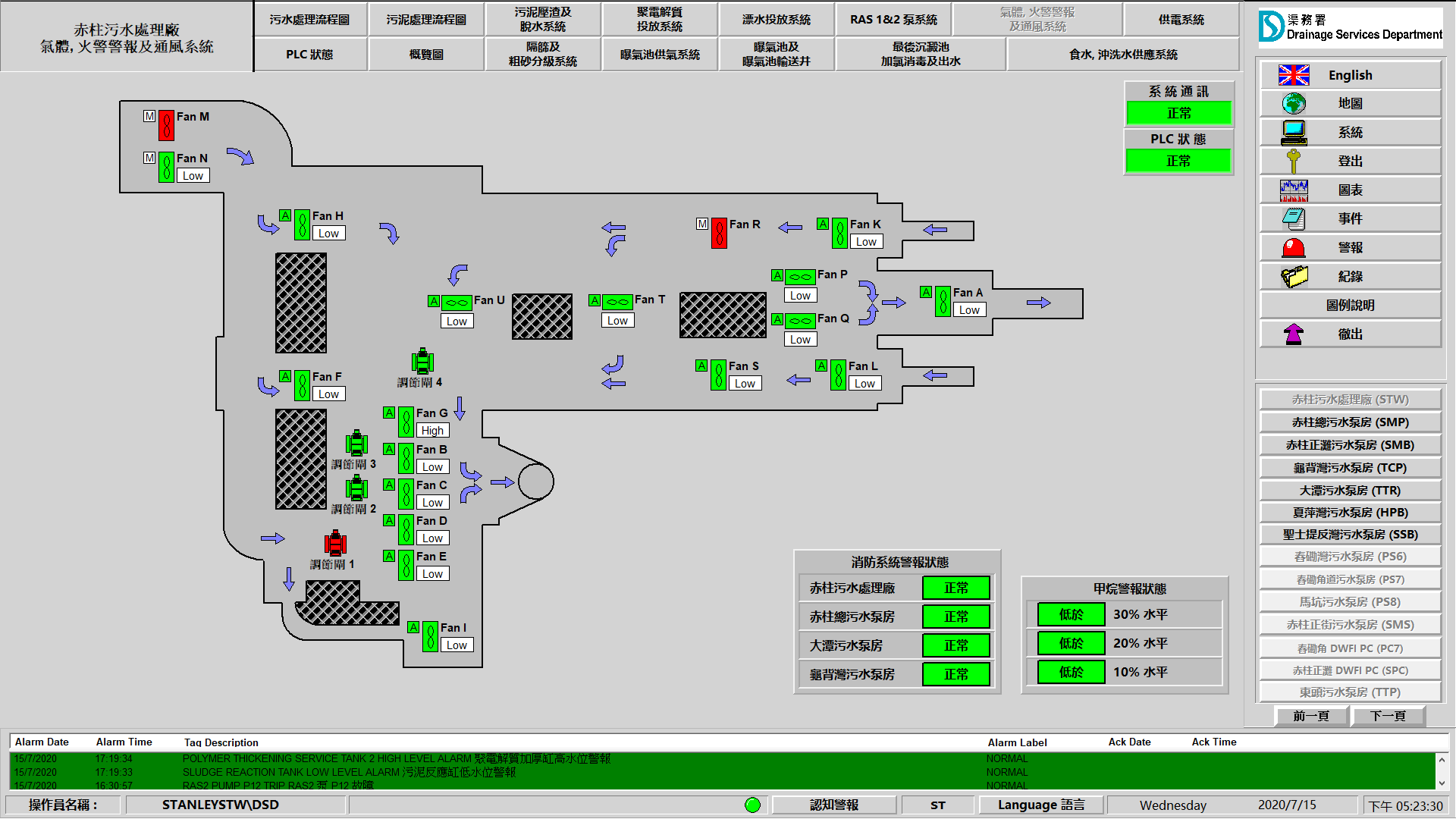

Part of Ventilation System (Typical)

Gas Detection & Fire Alarm Signal

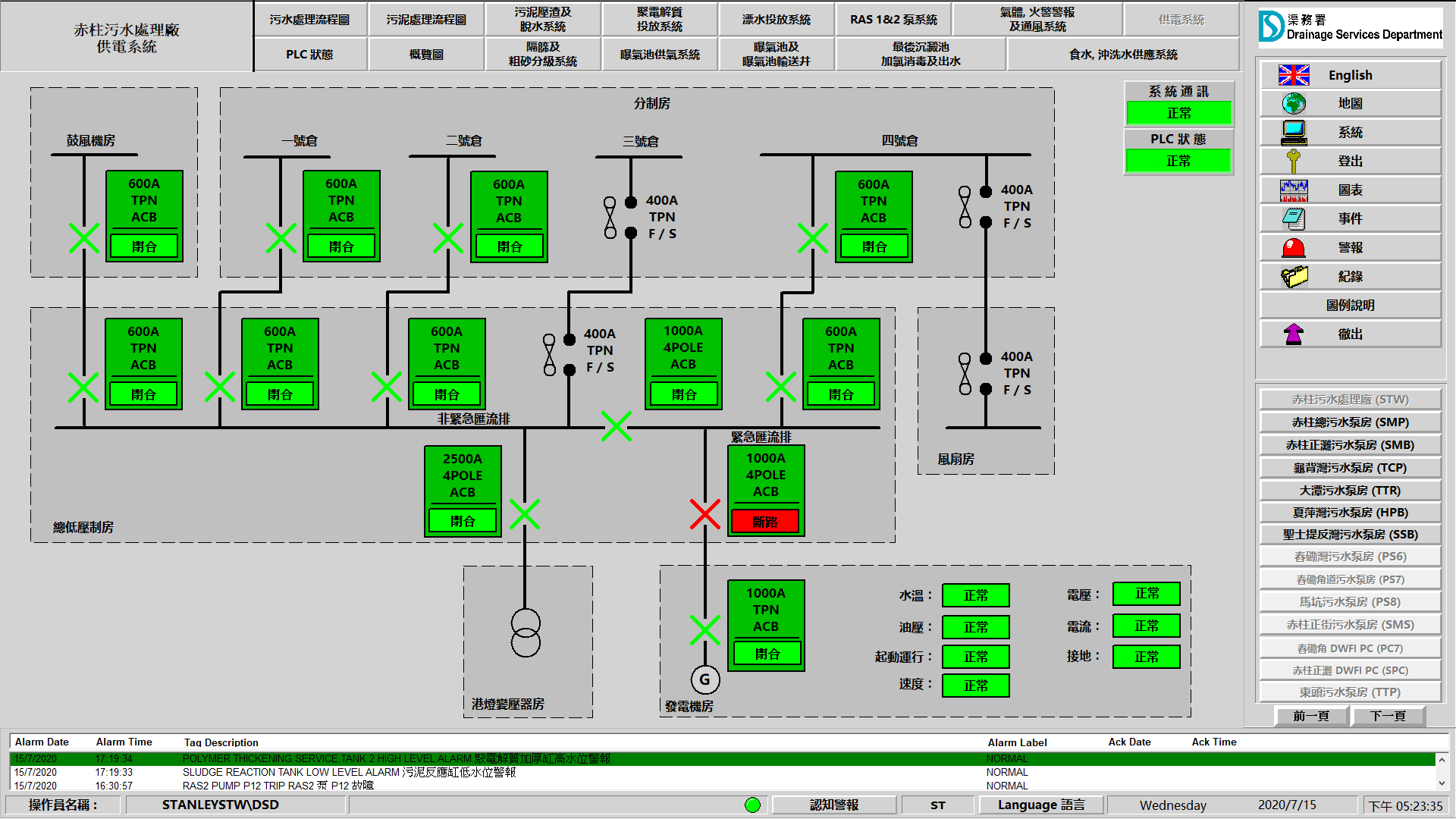

Power Supply System

Part of Inlet Screen System (Typical)

Part of Aeration Tank Air Supply System (Typical)

Part of Aeration Tank Recirculation Pumping System (Typical)

Part of Final Settlement Tank System (Typical)

Part of Washwater Supply System

Part of Stanley Main Pumping Station Inlet Chamber (Typical)

Part of Stanley Main Pumping Station Sump Pump System (Typical)

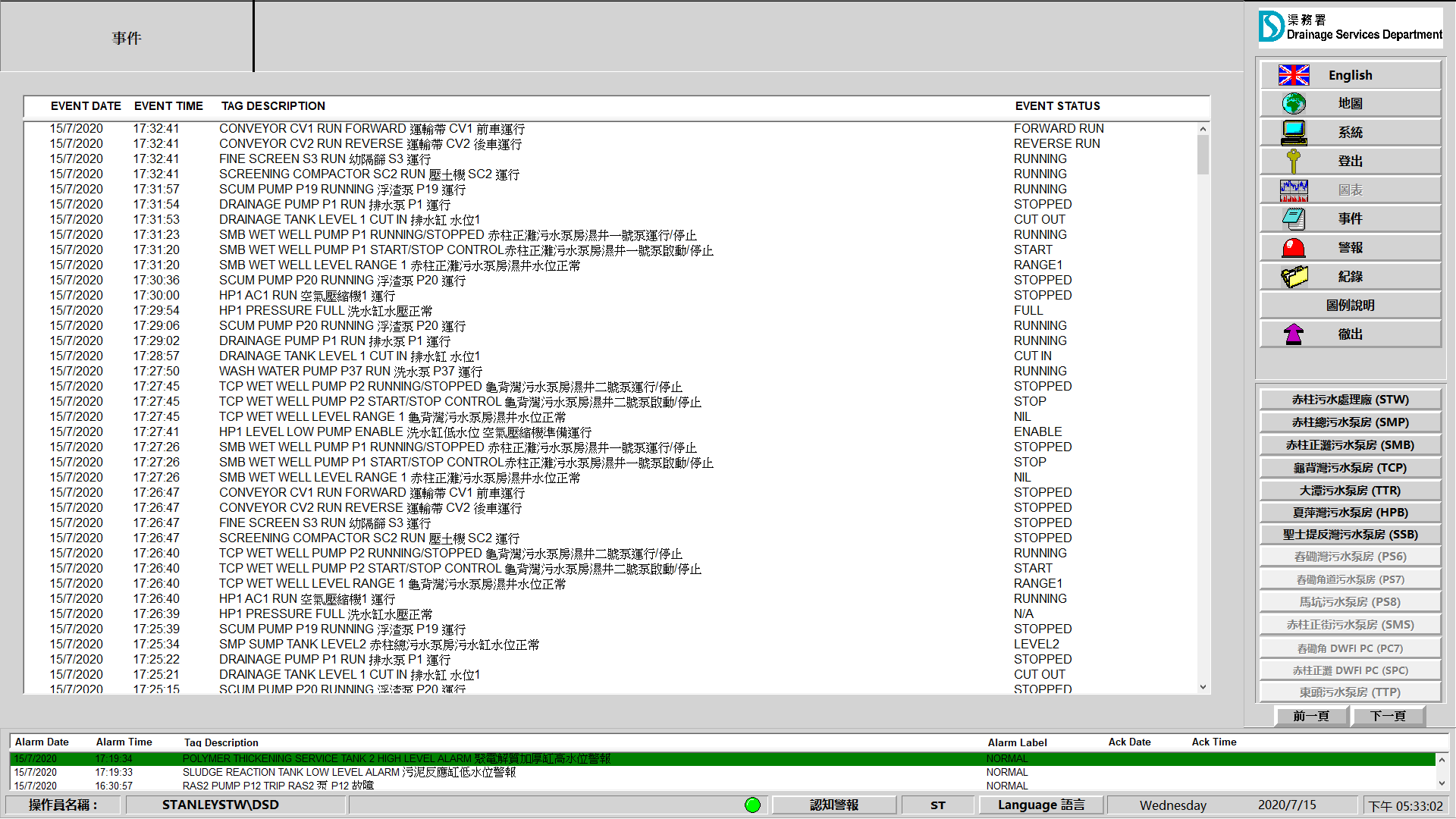

Alarm Summary page

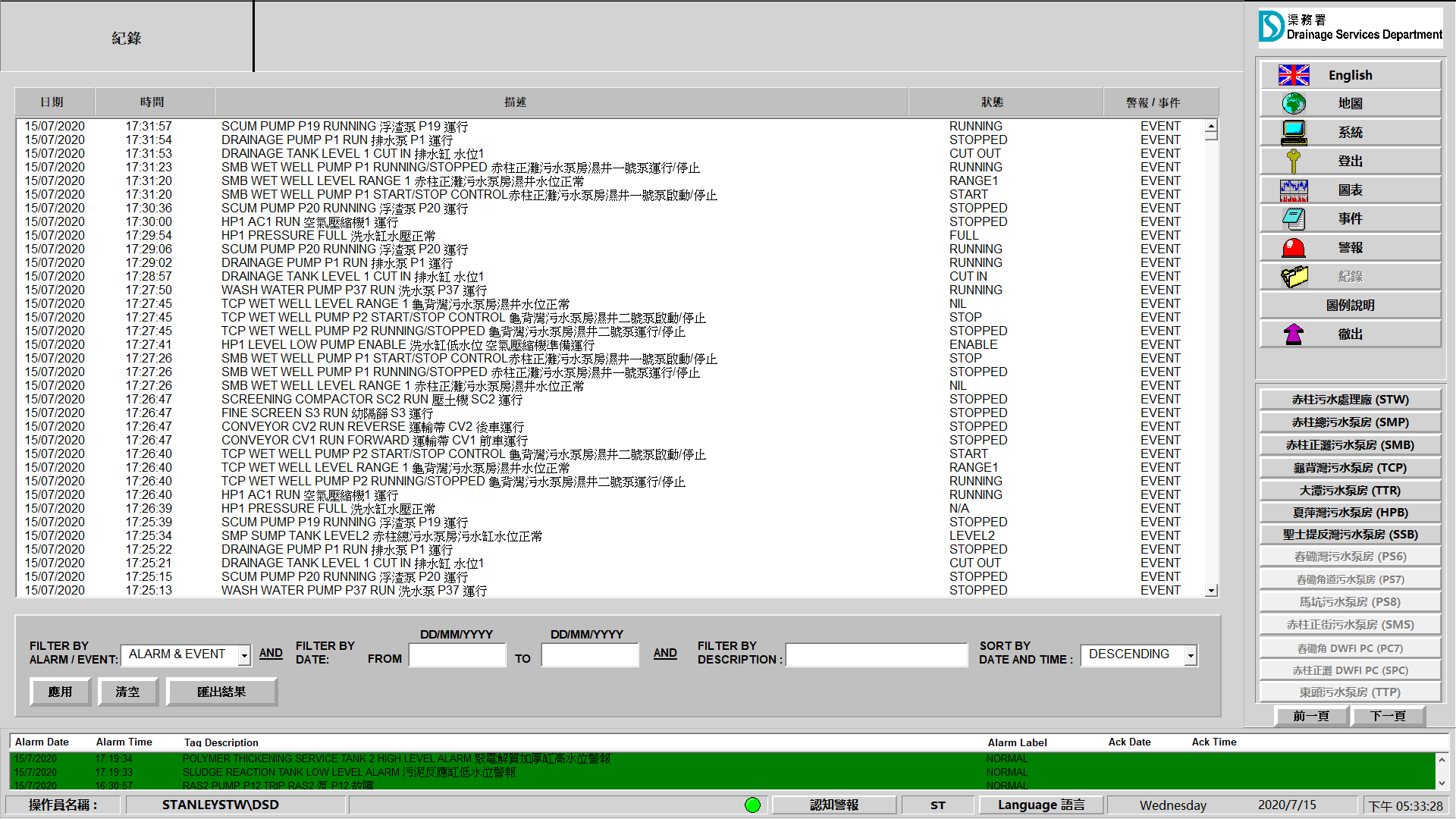

After Works (Screenshots captured from FactoryTalk View)

Sludge Press & Dewatering System

Polyelectrolyte Dosing System

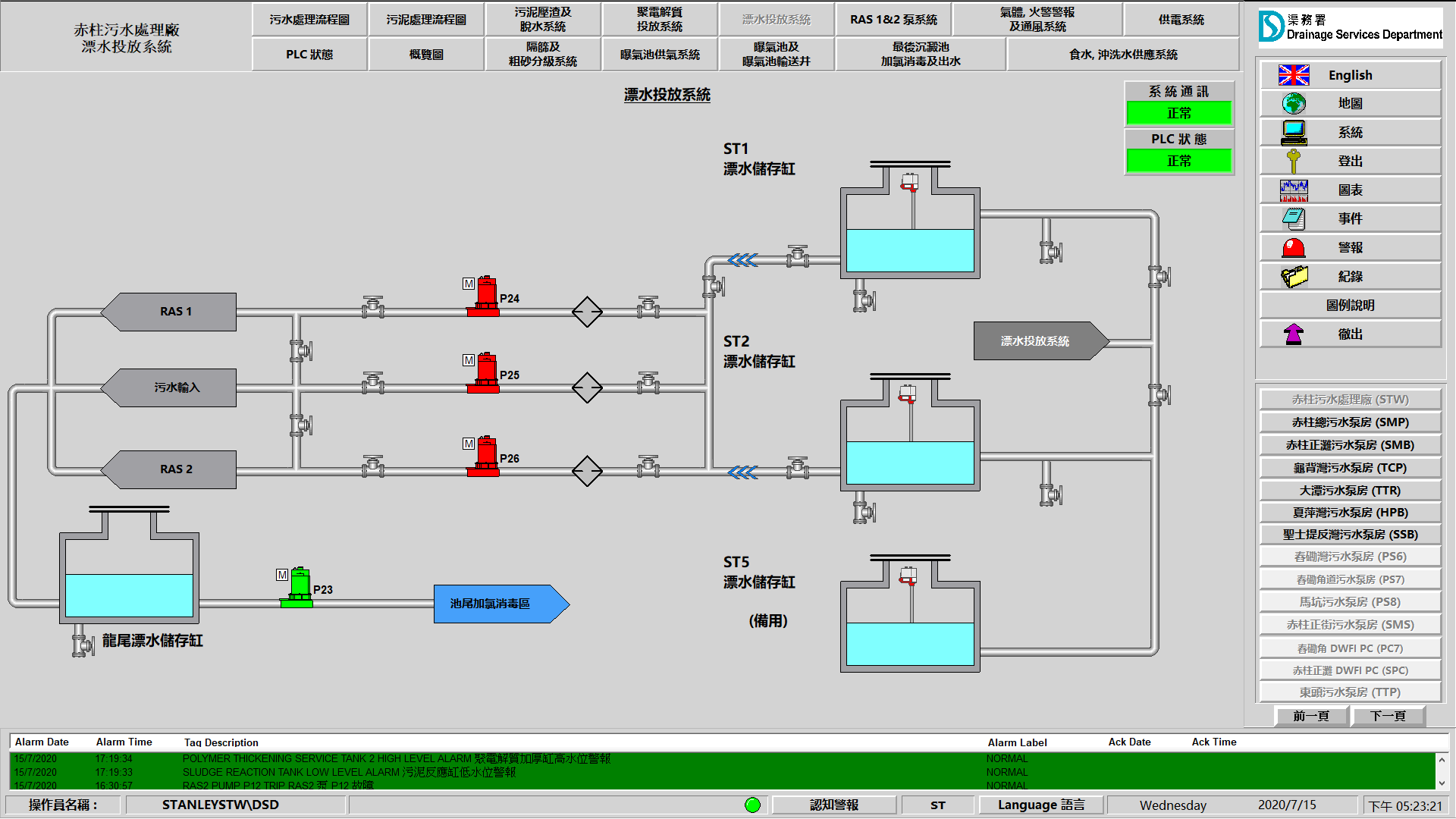

Hypochlorite Dosing System

RAS Pump Station

GAS Detection, Fire Alarm & Ventilation System

Power Supply System

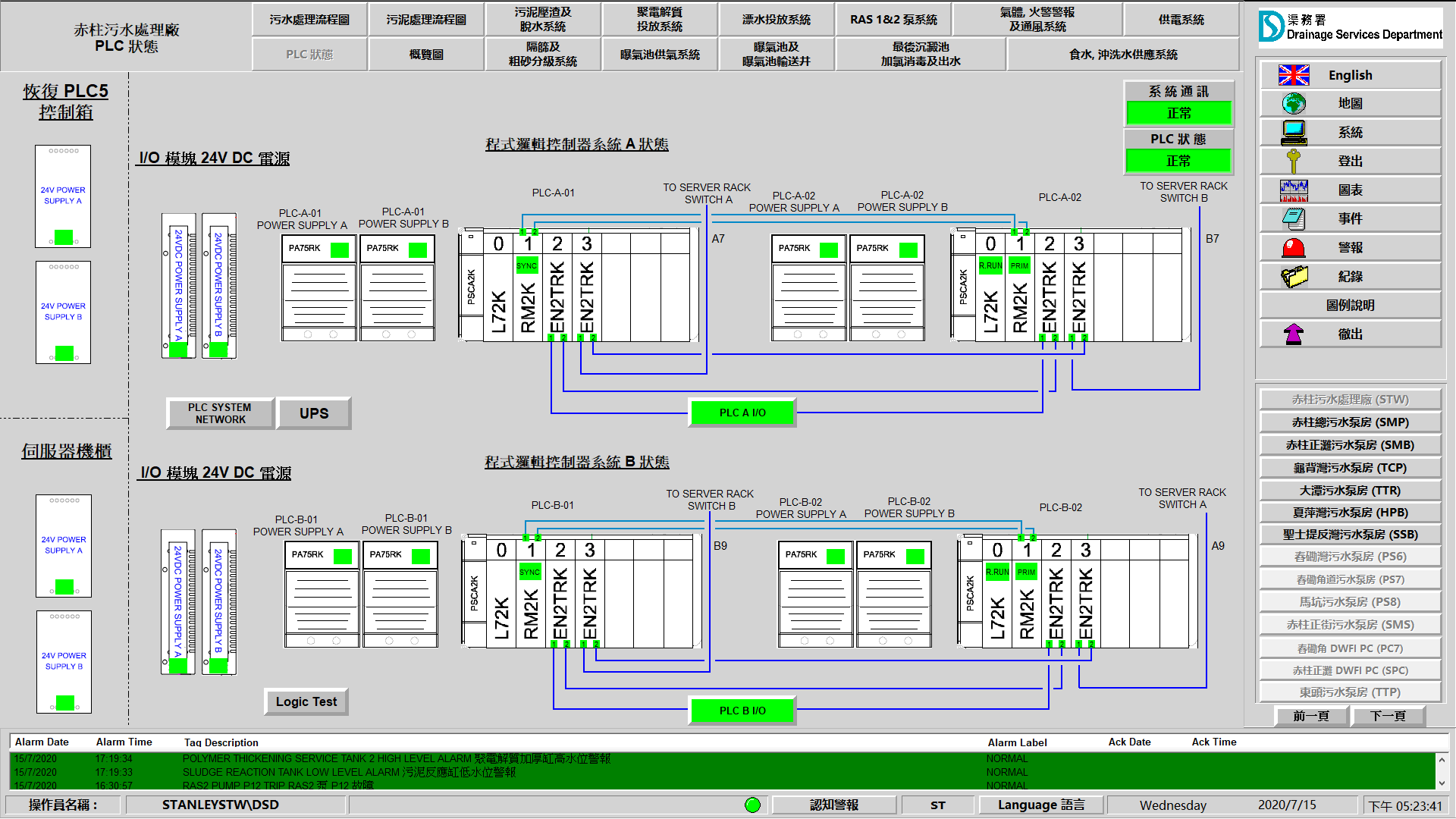

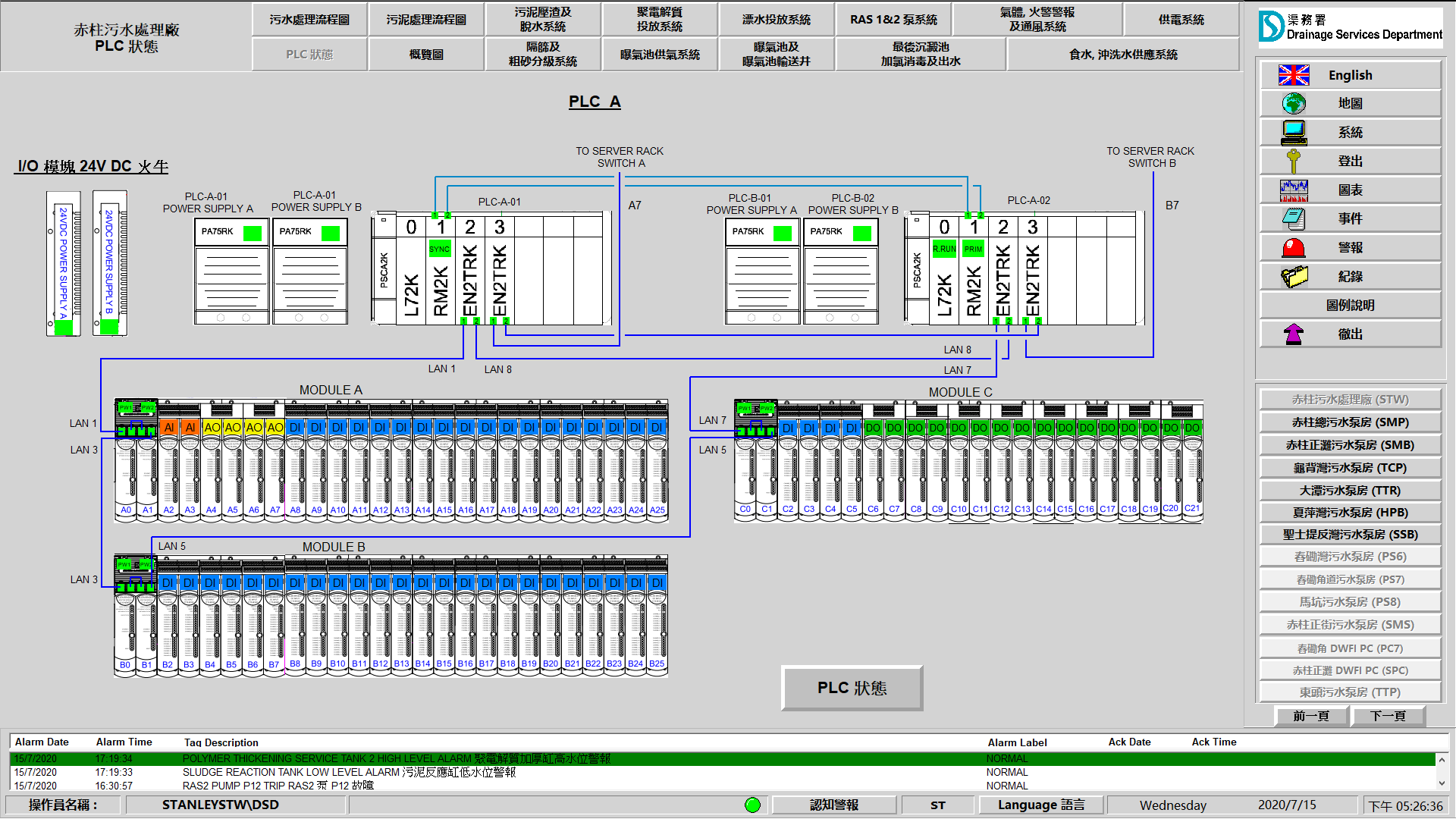

New PLC System Status page (Typical)

New PLC System I/O configuration & Status page (Typical)

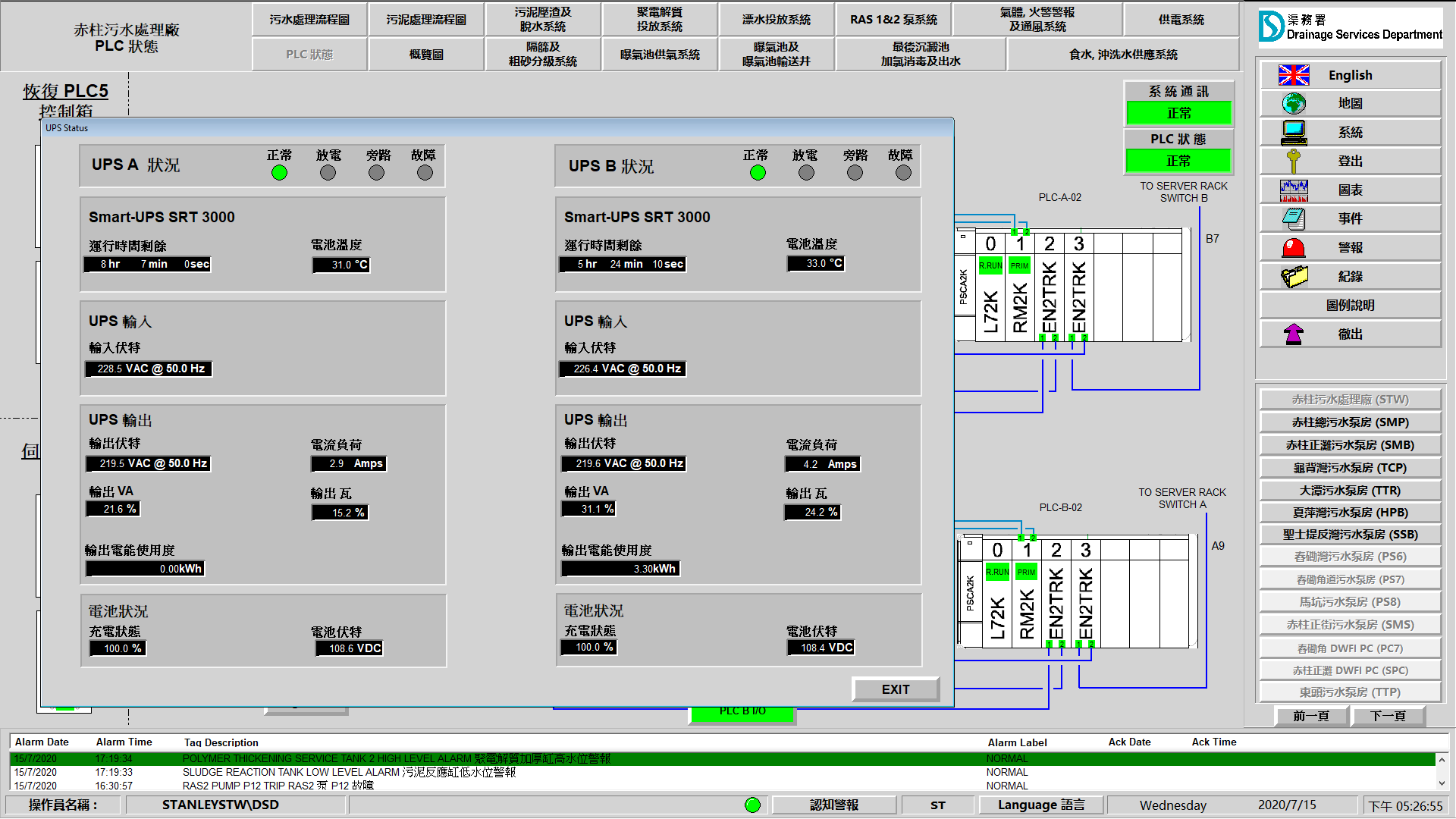

New UPS System Status page

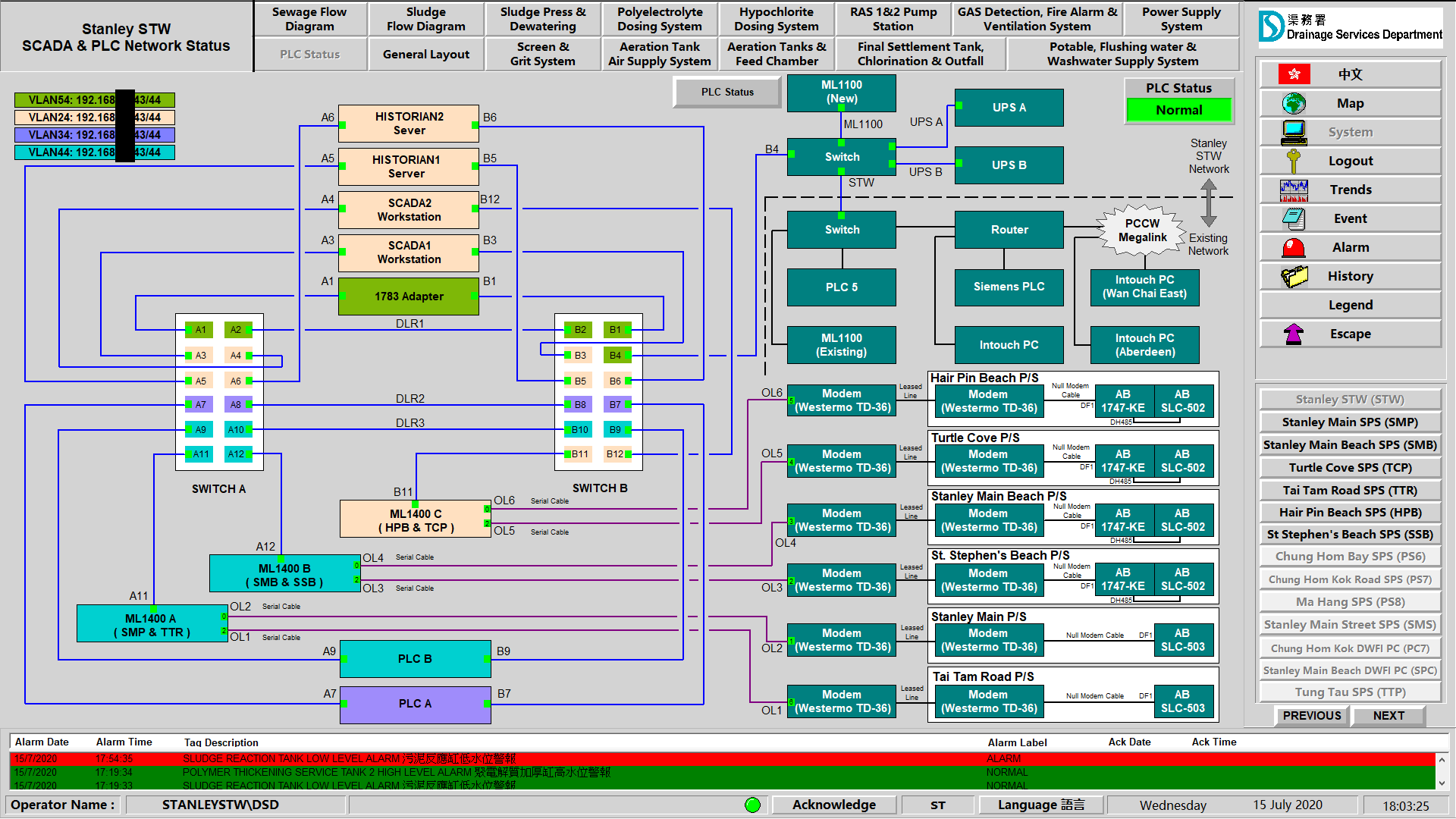

New SCADA & PLC Network Diagram page

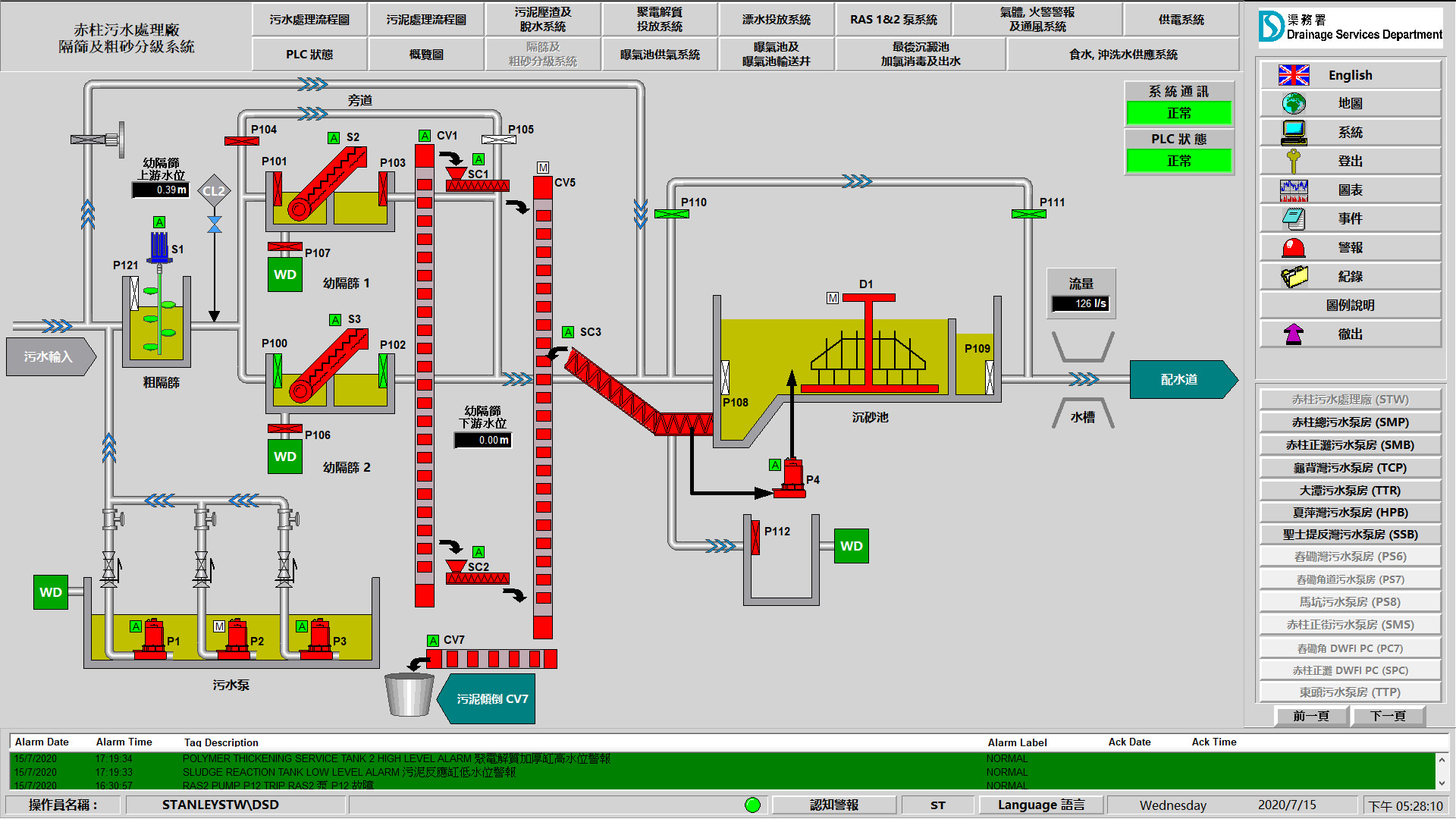

Scren & Grit System

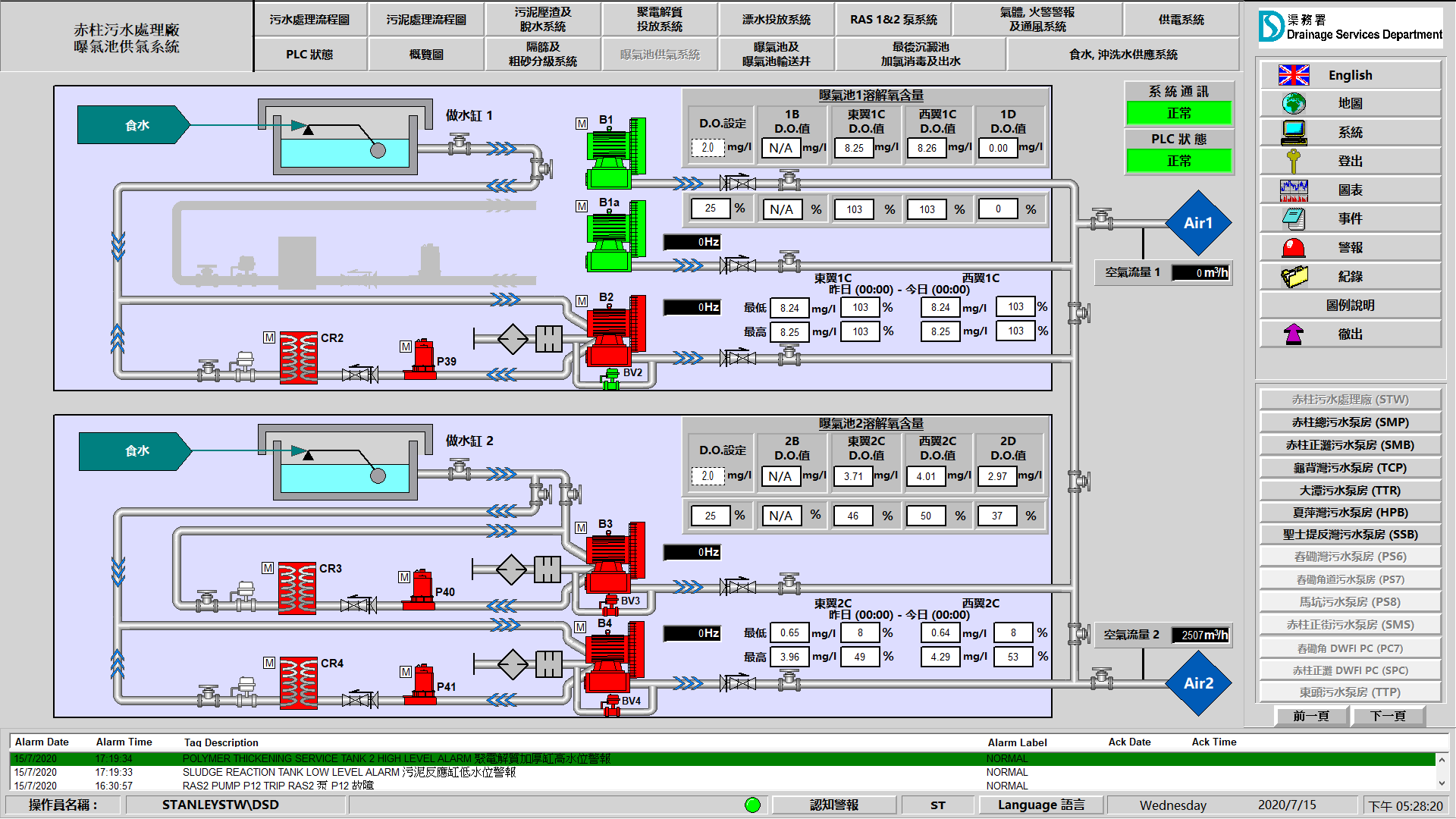

Aeration Tank Air Supply System

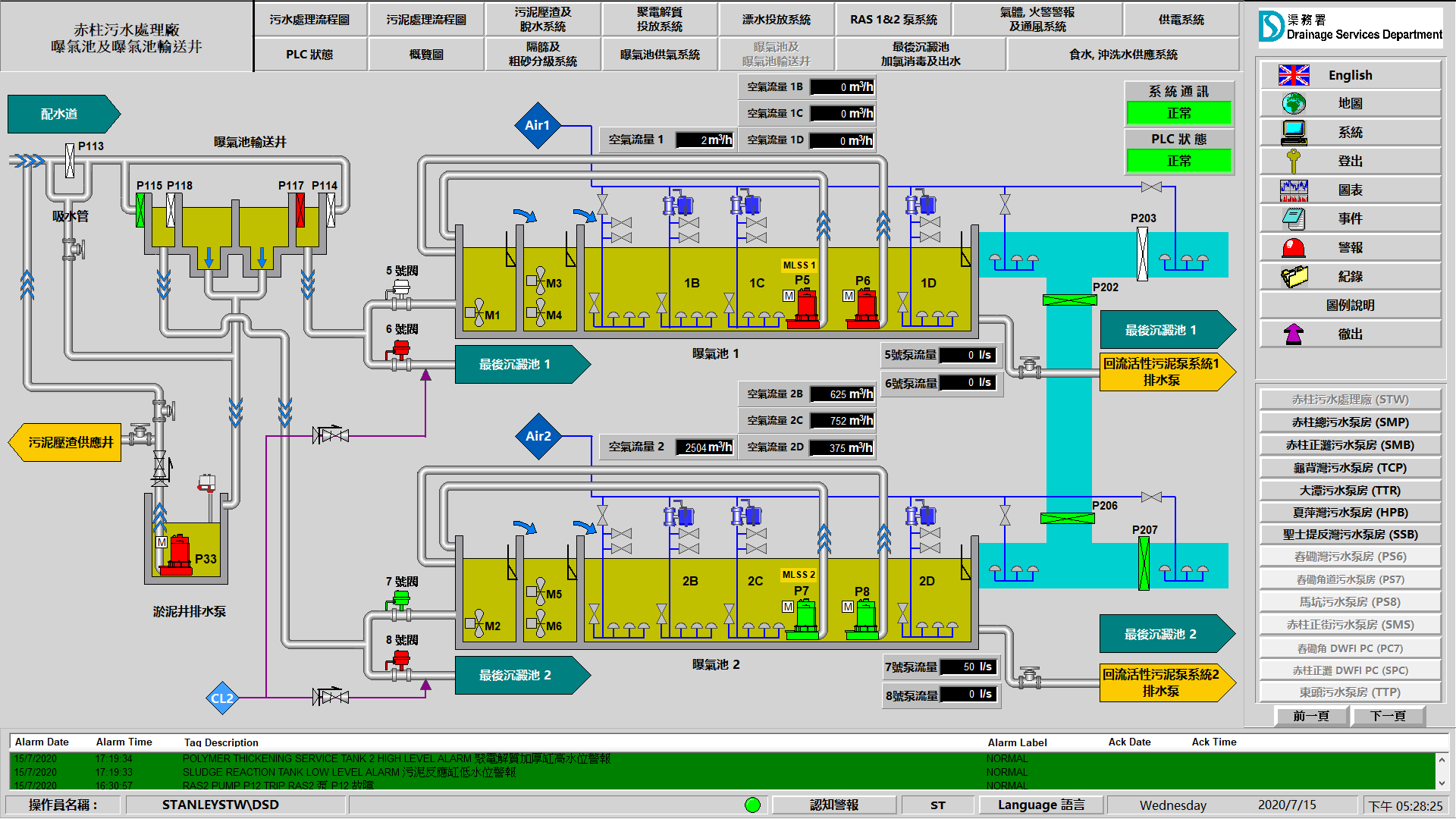

Aeration Tank & Feed Chamber

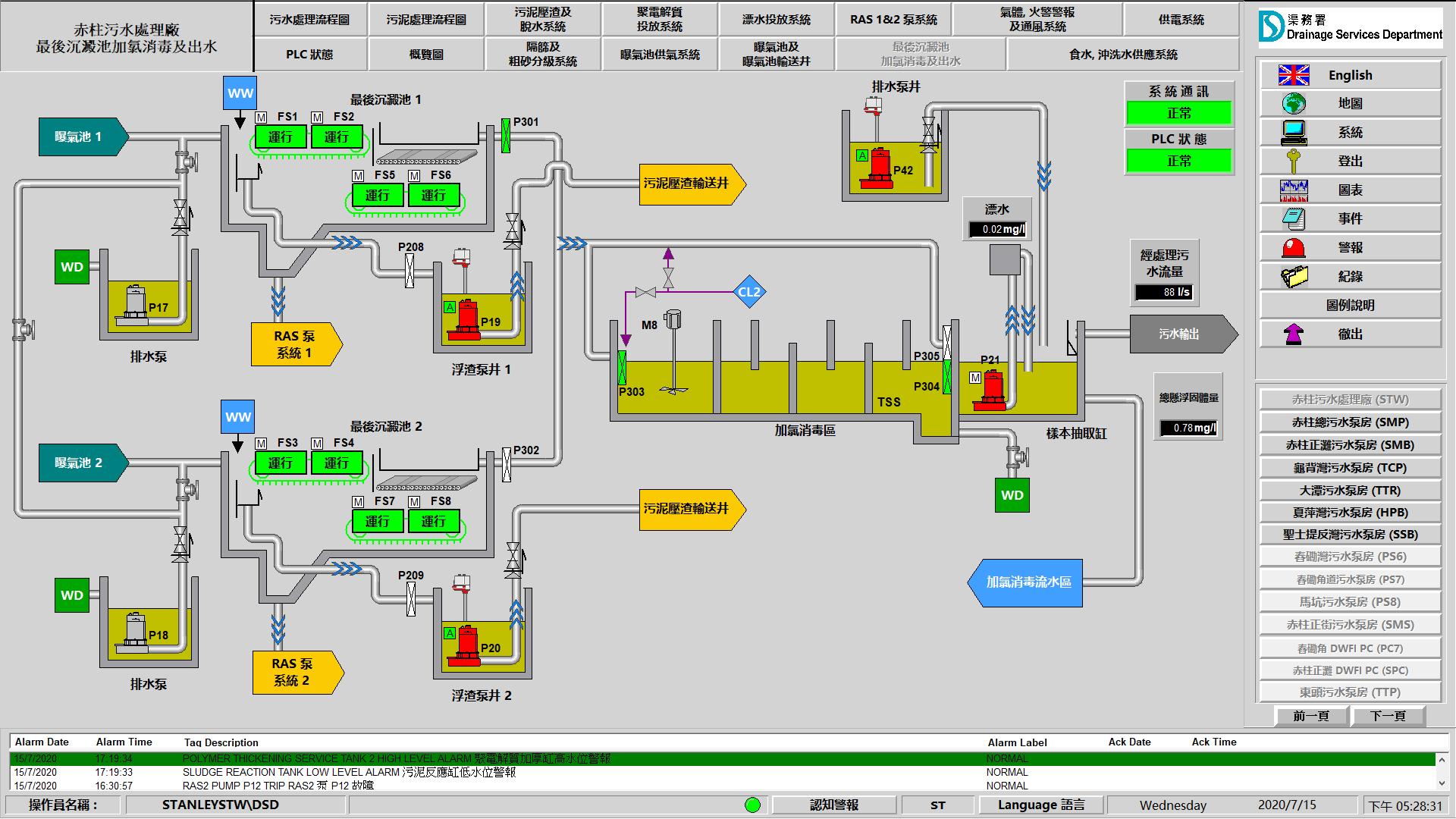

Final Settlement Tank, Chlorination & Outfall page

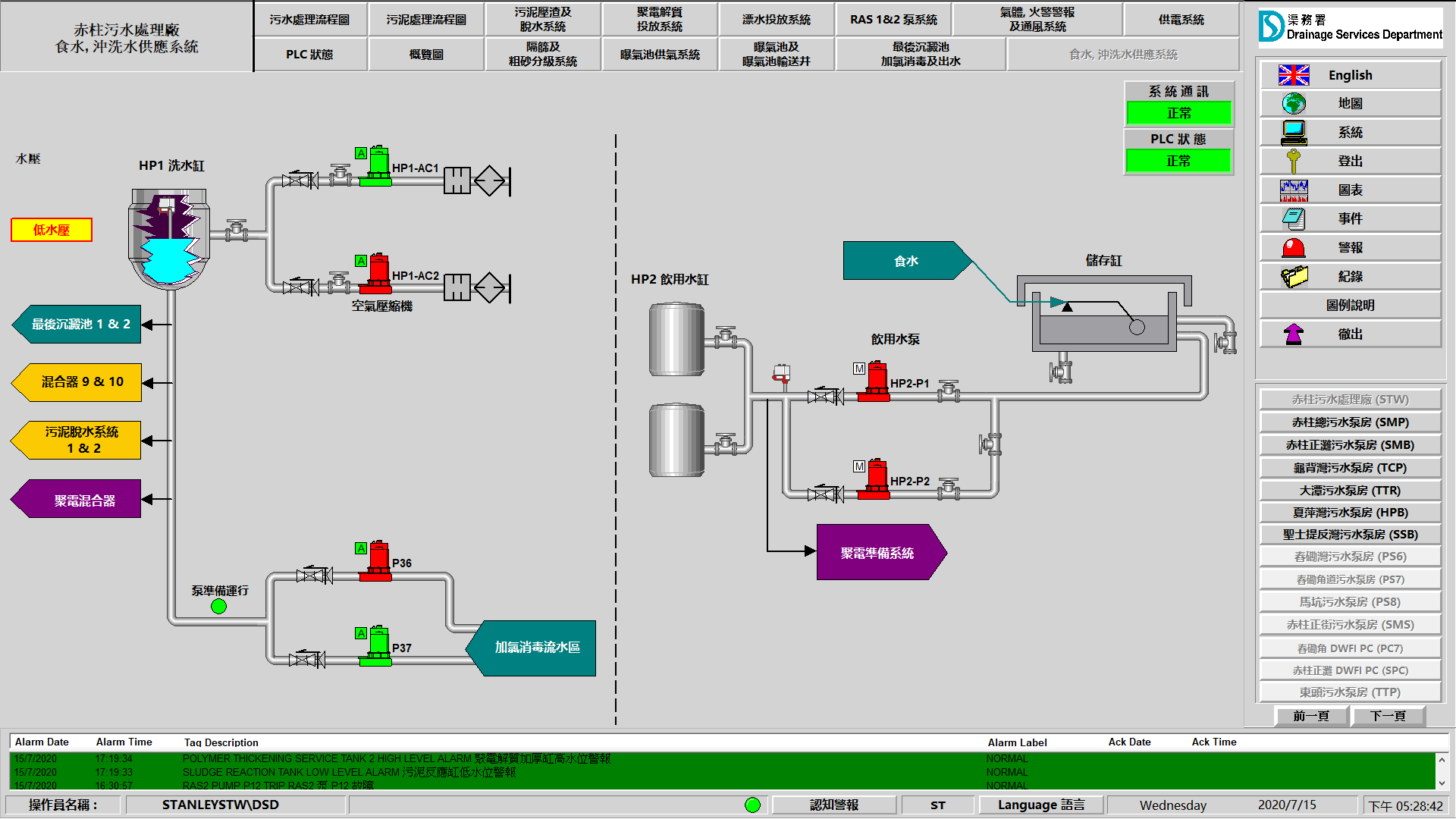

Potable, Flushing Water & Wastewater Supply System

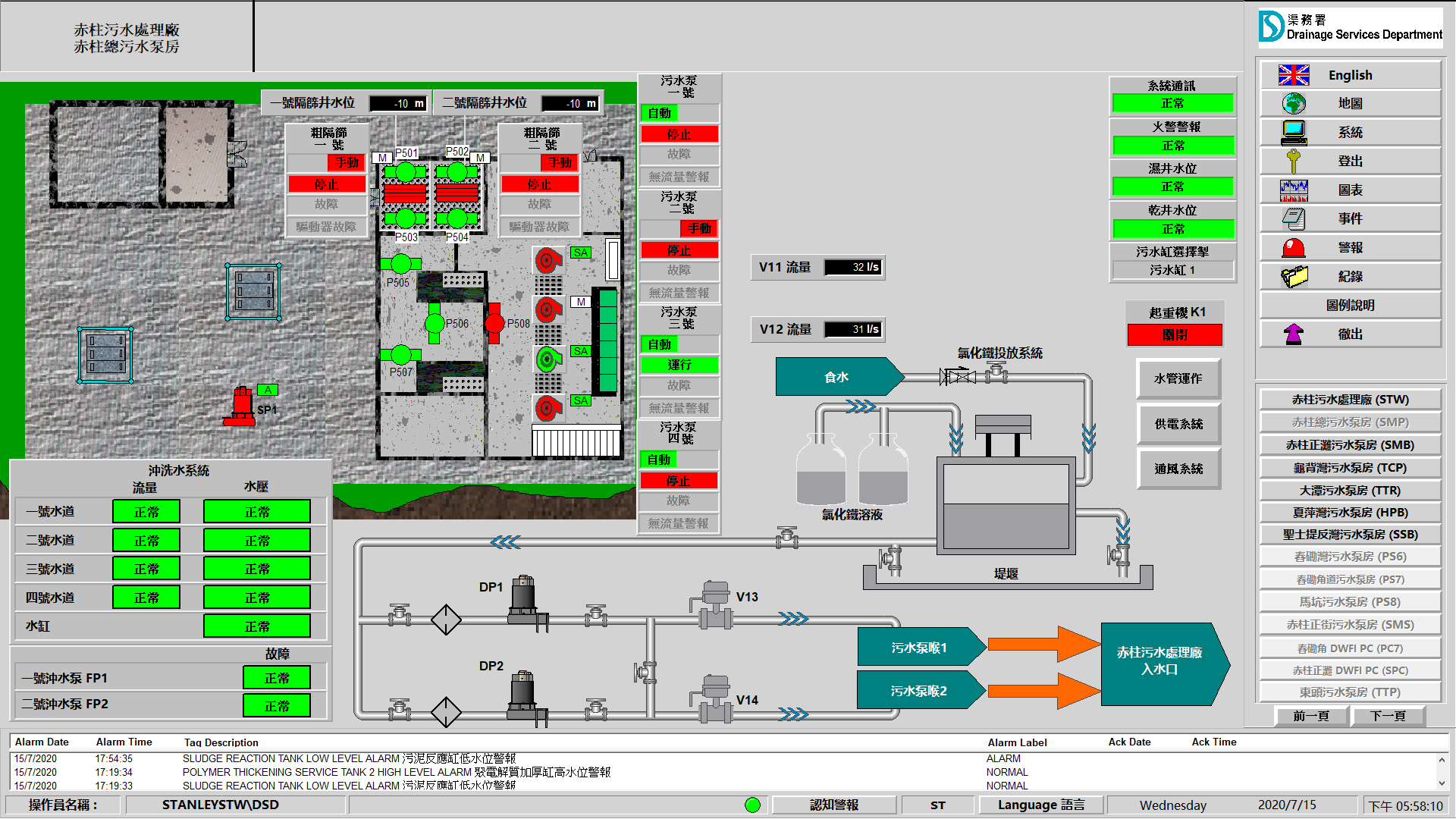

Stanley Main Sewage Pumping Station Overview page (Typical)

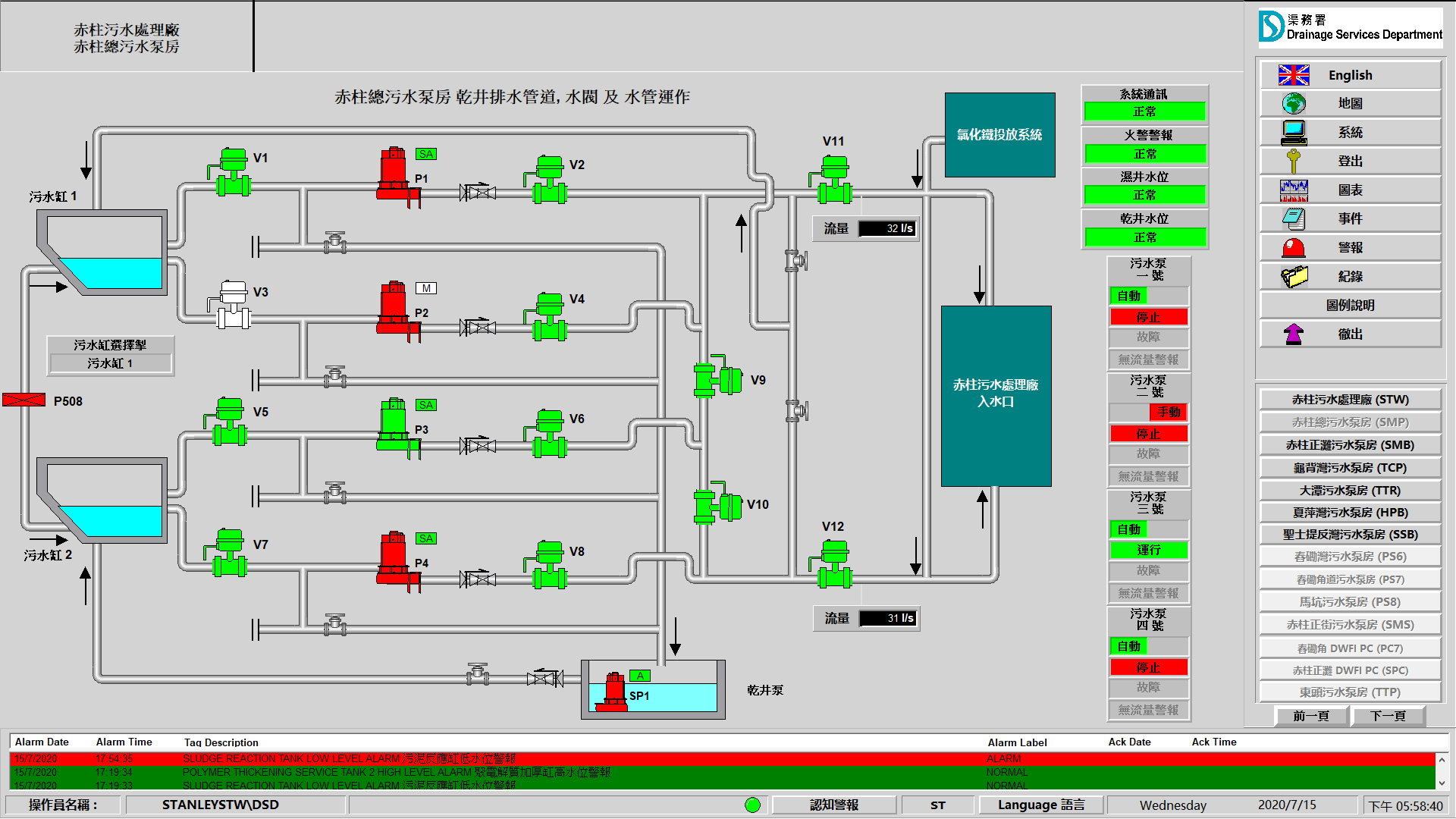

Stanley Main Sewage Pumping Station Valve Status page

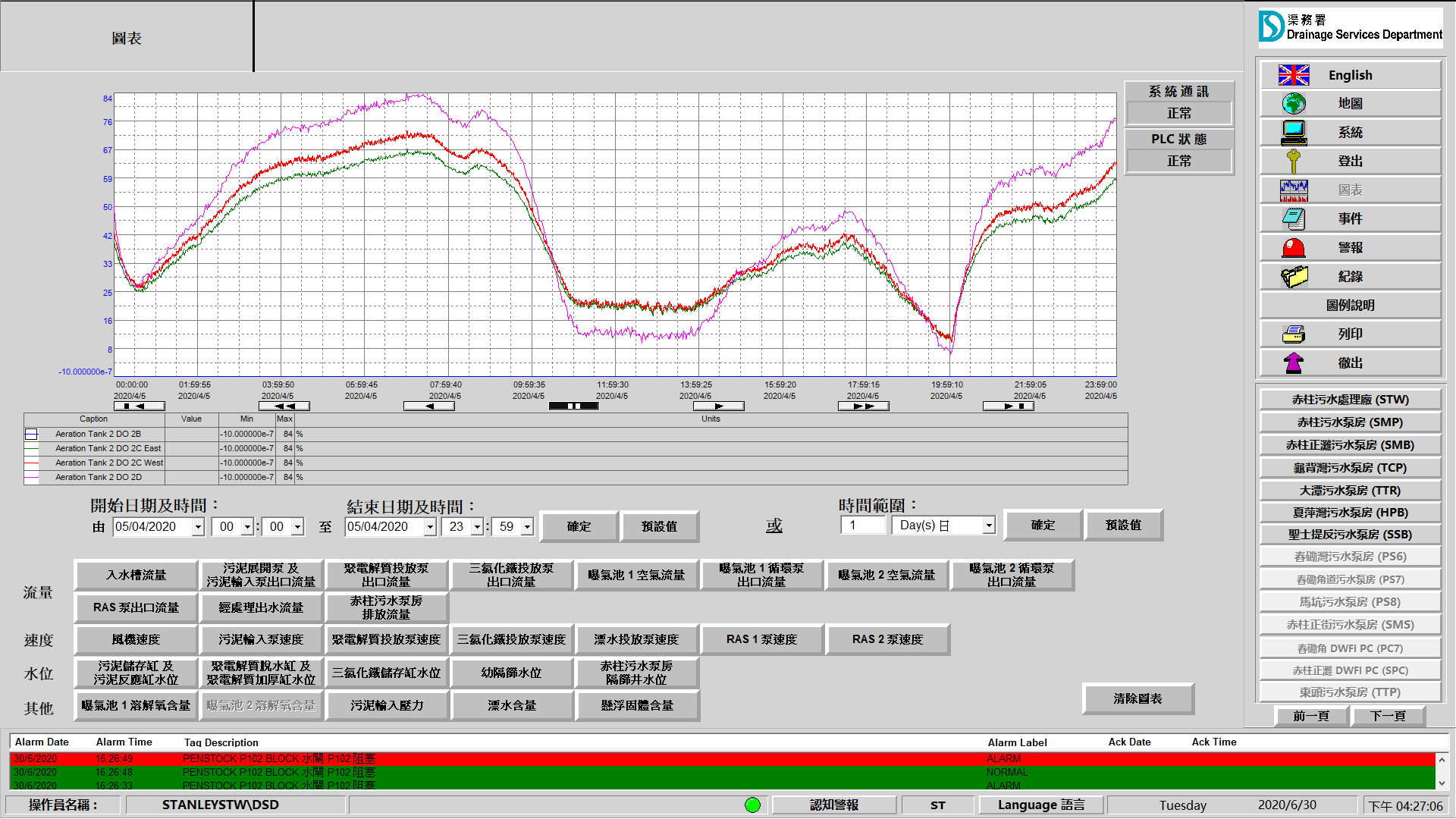

Trending Page (Typical)

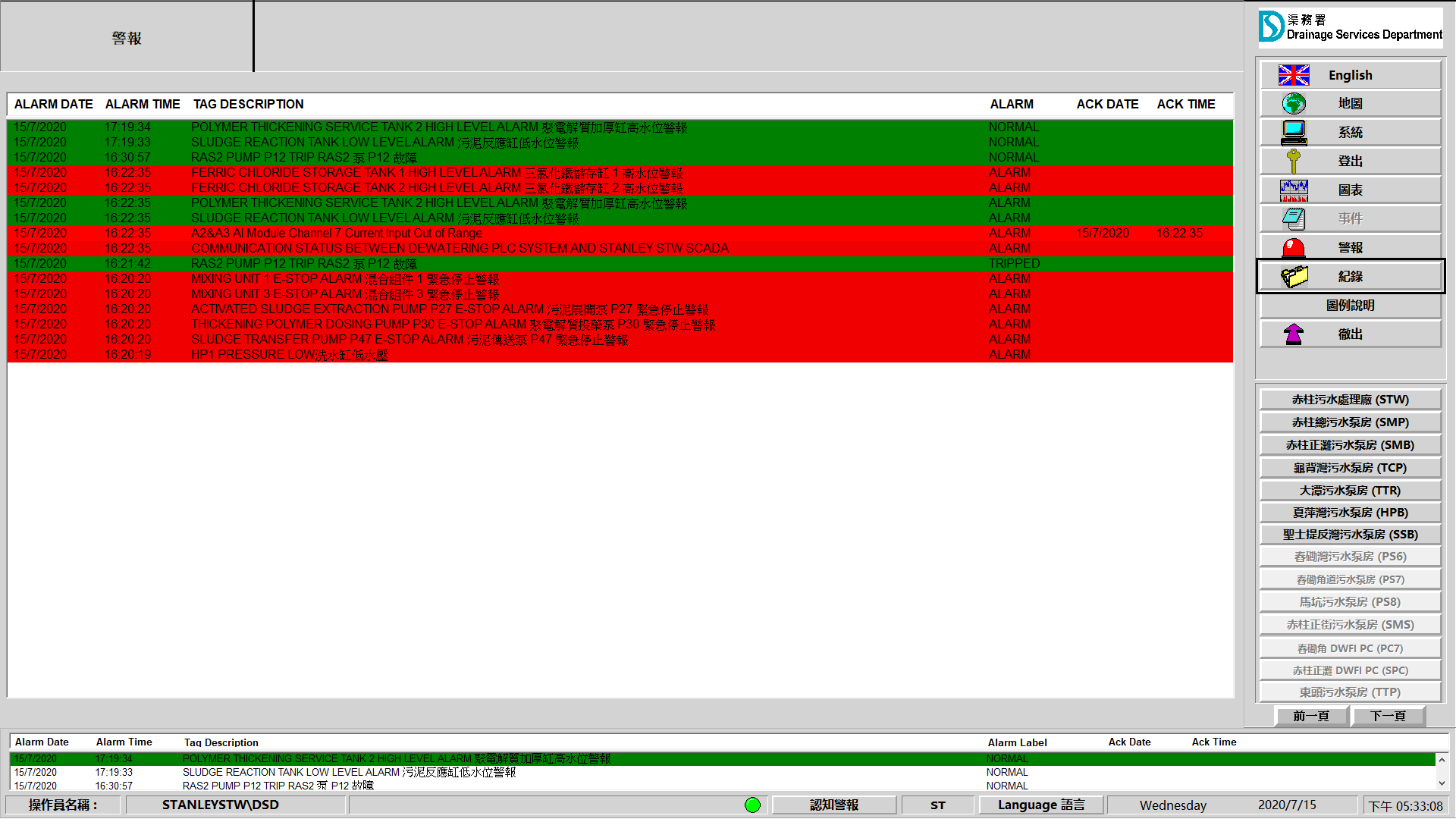

Alarm Summary Page

Event Summary Page

Alarm/Event History Page